Lanyard production process two - silk screen process

In the previous article, a process for making lanyards - thermal transfer printing process, today, let's talk about another lanyard production process, silk screen printing process.

Screen printing is also called screen printing. The basic principle is: use the basic principle that the mesh of the graphic part of the screen printing plate is transparent to the ink, and the mesh of the non-graphic part is impermeable to the ink. When printing, pour ink on one end of the screen printing plate, apply pressure on the ink part of the screen printing plate with a squeegee, and move toward the other end of the screen printing plate at the same time. The ink is squeezed onto the substrate by the scraper from the mesh of the graphic part during the movement.

There are three printing methods:

1. Direct plate making method

When making a plate, first place the photosensitive film on the wrist film base coated with the photosensitive material on the work surface, lay the stretched wrist screen frame flat on the film base, and then put the photosensitive paste in the screen frame and use a soft scraper The plate is press-coated, and the plastic base is peeled off after being fully dried. The wrist screen with the photosensitive film is attached and it can be used for printing. After developing and drying, the screen printing screen is made.

2. Indirect plate making method

The indirect film is first exposed, hardened with 1.2% H2O2 and developed with warm water. After drying, a peelable graphic negative is made. When making a plate, the graphic negative film surface is tightly attached to the stretched screen, and the film is squeezed to make the film. Stick it with the wet screen, peel off the film base, and dry it with the wind to make the screen printing screen.

3. Straight mixing plate making method

First, the photosensitive adhesive layer is pasted on the screen frame with water, alcohol or photosensitive adhesive. After drying with hot air, the base of the photosensitive film is removed, and then the plate is printed. After developing, the screen plate is made.

-

Such a beautiful keychain makes people love and hate!

Such a beautiful keychain makes people love and hate!If you are a designer, then lines like "Tune a little bit here", "Help me change t...

Do you like ?0

Read more -

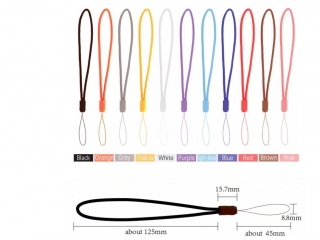

Easy to carry Water Bottle Lanyards buying

Easy to carry Water Bottle Lanyards buying -

Advantages of using personalized printed Silicone Wristbands

Advantages of using personalized printed Silicone Wristbands -

The difference between nylon lanyard vs polyester lanyard - Yiyixing

The difference between nylon lanyard vs polyester lanyard - YiyixingWhat is Polyester Made Lanyards?

When it comes to <...

Do you like ?0

Read more -

Does Wear Cute lanyard can keep in a good mood?

Does Wear Cute lanyard can keep in a good mood?With the growth of age, girls are more and more inclined to adorabl...

Do you like ?0

Read more -

Why not choosing custom flight tags as a gift?

Why not choosing custom flight tags as a gift?Fabric key tag, made by embroidery or woven is one of our new appli...

Do you like ?0

Read more