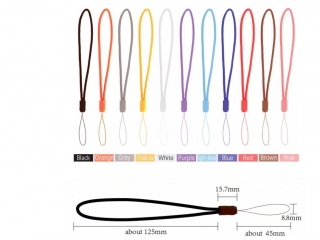

Lanyard Making Process - Webbing

It can be roughly divided into three major links: webbing, printing, and assembly. There are other details involved in each link, please see the specific content below.

Ribbon

1 Prepare the yarn

For silk screen printing, if the color of the lanyard requested by the customer is a common color, such as red, black, etc., you can directly buy the yarn and then weave it; if it is a color that is not commonly used, the factory will buy white yarn and dye it yourself Then weave the belt.

2 barrels

The yarn bought from the factory or the yarn after dyeing needs to be wound into a barrel thread suitable for the loom. The factory machine uses iron loops, and the purchased thread is not suitable for direct wrapping on the machine.

3 webbing

The worker puts the wound thread on the weaving machine for weaving. When weaving, the white one is usually more dirty, so a special machine is needed to produce it. After weaving, it is placed in a fixed place. , can be used.

Some ribbons are woven flat, while others are round.

-

Such a beautiful keychain makes people love and hate!

Such a beautiful keychain makes people love and hate!If you are a designer, then lines like "Tune a little bit here", "Help me change t...

Do you like ?0

Read more -

Easy to carry Water Bottle Lanyards buying

Easy to carry Water Bottle Lanyards buying -

Advantages of using personalized printed Silicone Wristbands

Advantages of using personalized printed Silicone Wristbands -

The difference between nylon lanyard vs polyester lanyard - Yiyixing

The difference between nylon lanyard vs polyester lanyard - YiyixingWhat is Polyester Made Lanyards?

When it comes to <...

Do you like ?0

Read more -

Does Wear Cute lanyard can keep in a good mood?

Does Wear Cute lanyard can keep in a good mood?With the growth of age, girls are more and more inclined to adorabl...

Do you like ?0

Read more -

Why not choosing custom flight tags as a gift?

Why not choosing custom flight tags as a gift?Fabric key tag, made by embroidery or woven is one of our new appli...

Do you like ?0

Read more