Lanyard Making Process - Printing - Assembling

It can be roughly divided into three major links: webbing, printing, and assembly. There are other details involved in each link, please see the specific content below.

2. Printing (the lanyard printing part is divided into two types: silk screen printing and thermal transfer printing)

(1) Screen printing process:

1 ironing

The newly woven lanyard is not flat and needs to be ironed with an ironing machine before printing.

2 printing

When the factory is actually printing, there are two methods that are commonly used at present: screen printing and thermal transfer printing.

3 Screen printing

① Fix the lanyard on the printing table. There is a layer of primer on the table to fix the lanyard and prevent the lanyard from moving during the printing process. This glue generally does not stick to the surface of the lanyard.

② The production of silk screen version. After the technician gets the original logo, he first traces the drawing, and then makes the film called the film.

"Film" is the transliteration of "Film". Film is a transparent film with a film on one side called a matte surface, and a film without a film on the other side to reflect light. The matte surface is not very reflective. If you have seen the bottom of the traditional photo, you will know that the principle is the same, but the composition of the film base and the medicine film are different. The film is divided into four colors (CMYK) and spot color film. There are four things like slides that are stacked together to form a complete color image, which needs to be taken to the printing house to make the plate and divided into four overprints.

The screen printing plate is a screen printing plate made by using photosensitive material by photo-engraving method (the screen holes of the graphic part on the screen printing plate are through holes, and the screen holes of the non-graphic part are blocked). During printing, through the extrusion of the squeegee, the ink is transferred to the substrate through the mesh of the graphic part to form the same graphic as the original. Screen printing equipment is simple, easy to operate, easy to print and plate making, low cost, and strong adaptability. Screen printing is widely used in common prints: color oil paintings, posters, business cards, binding covers, commodity signs, and printed and dyed textiles.

③ Because it is printed by means of through-hole ink leakage, several screen versions of the Logo have to be opened for several colors. Several screen versions of different colors form a complete logo.

④ Fix the screen printing plate in the wooden frame and start printing. Use the corresponding color ink for each plate, and use the squeegee to squeeze the through hole part. There are obvious signs on the printing table, the operator can know the movement The interval of the frame, the interval of each move is the same.

⑤ After printing this side, stick it on the desktop and start printing the other side

⑥ Screen printing may appear incomplete printing, you can see if you want to repeat the screen printing according to the situation.

⑦ After screen printing, the logo should be dried.

(2) The thermal transfer process of the lanyard:

① Process introduction. Thermal transfer printing is a new printing process that has been introduced from abroad for more than 10 years. The process printing method is divided into two parts: transfer film printing and transfer processing. The transfer film printing adopts dot printing (resolution up to 300dpi), and the pattern is pre-printed on the surface of the film. The printed pattern is rich in layers, bright in color and ever-changing. , small chromatic aberration, good reproducibility, can meet the requirements of the designer, and is suitable for mass production; transfer processing is processed by a thermal transfer machine (heating and pressing) to transfer the exquisite pattern on the transfer film to the product. The surface, after molding, the ink layer and the surface of the product are integrated, which is realistic and beautiful, which greatly improves the grade of the product. However, due to the high technical content of this process, many materials need to be imported.

② There are two types of films generally used. One is roll type and the other is sheet type. These papers are made by professional factories that make this kind of paper. The roll type is calculated according to the meter, while the The leaflet type is calculated according to the sheet, and it is cheaper to calculate the leaflet type.

Rolled: A continuous piece of paper, similar to the total length of the lanyard printed at one time. The lanyard and roll are rolled, contacted, and then heated in a heat transfer machine to print the logo on the roll to In the lanyard. The used drum is wrapped around another drum.

Sheet-fed: For sheets of paper, the factory needs to align the lanyard with the sheets of paper, and then heat them together in a heat transfer machine to print the pattern on the paper directly on the lanyard. The alignment method of the lanyard and the paper is to open a piece of paper, and then put the lanyard on the paper. The edge of the lanyard and the edge of the pattern are exactly opposite in size, and there should be no deviation, and then put them into the heat transfer machine together. inside.

Three, assembly.

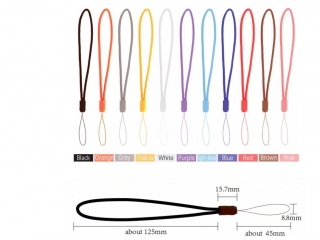

1 Cutting of lanyards. Since lanyards are screen-printed in batches, they should be cut into lanyards one by one after printing. There are generally two ways of positioning: one is to draw a corresponding line on the table, and the position is matched; The other is: marks are left during silk screen printing. In this way, the operator uses the steel wire to energize, presses down with the steel wire according to the mark, and uses high temperature to melt the lanyard to cut open. Use high temperature steel wire to cut to avoid wire drawing .

2 Assembly of accessories.

For sewing. You can trim the thread after sewing.

-

Such a beautiful keychain makes people love and hate!

Such a beautiful keychain makes people love and hate!If you are a designer, then lines like "Tune a little bit here", "Help me change t...

Do you like ?0

Read more -

Easy to carry Water Bottle Lanyards buying

Easy to carry Water Bottle Lanyards buying -

Advantages of using personalized printed Silicone Wristbands

Advantages of using personalized printed Silicone Wristbands -

The difference between nylon lanyard vs polyester lanyard - Yiyixing

The difference between nylon lanyard vs polyester lanyard - YiyixingWhat is Polyester Made Lanyards?

When it comes to <...

Do you like ?0

Read more -

Does Wear Cute lanyard can keep in a good mood?

Does Wear Cute lanyard can keep in a good mood?With the growth of age, girls are more and more inclined to adorabl...

Do you like ?0

Read more -

Why not choosing custom flight tags as a gift?

Why not choosing custom flight tags as a gift?Fabric key tag, made by embroidery or woven is one of our new appli...

Do you like ?0

Read more