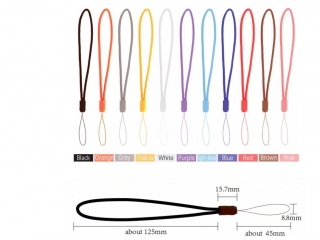

The production process of the lanyard

Textile is a traditional Chinese industry with a long history. As early as the Tang Dynasty, Chinese textiles have crossed the vast ocean and benefited mankind in the world. Today, the textile industry is still a strong industry in China.

A small lanyard actually requires a lot of processes. The following is an example of the production process of radio lanyards, toy lanyards, flashlight lanyards, and camera lanyards.

1. Ribbon: Generally, the materials for making lanyards are nylon, pp, polyester, and high-elastic cotton. The general specifications are 4mm, 5mm, 6mm, 7mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm in width.

2. Accessories: Common accessories include metal hook buckles, document clips, etc., and plastic ones include aircraft buckles, buckles, safety buckles, etc.

3. Printing: General exhibition lanyards will require the text and patterns that need to be promoted.

4. Assembly: First print, cut to the specified size, add strings, plastic buttons, dispense glue or press metal iron sheets, and then pack.

After inspection, a lanyard is ready for shipment.

Scope of application

A wide range of lanyards are used: electronic U disk, bank U shield, employee badges, exhibition cards, mini stereos, mobile phones, flashlights, work cards, ballpoint pens, tags, slings, etc. Any electronic product that needs to be easily carried can be used.

Lanyard material

There are Tedlon (polyester, poly), nylon, PVC, PU, silicone, resin, metal, etc.;

-

Such a beautiful keychain makes people love and hate!

Such a beautiful keychain makes people love and hate!If you are a designer, then lines like "Tune a little bit here", "Help me change t...

Do you like ?0

Read more -

Easy to carry Water Bottle Lanyards buying

Easy to carry Water Bottle Lanyards buying -

Advantages of using personalized printed Silicone Wristbands

Advantages of using personalized printed Silicone Wristbands -

The difference between nylon lanyard vs polyester lanyard - Yiyixing

The difference between nylon lanyard vs polyester lanyard - YiyixingWhat is Polyester Made Lanyards?

When it comes to <...

Do you like ?0

Read more -

Does Wear Cute lanyard can keep in a good mood?

Does Wear Cute lanyard can keep in a good mood?With the growth of age, girls are more and more inclined to adorabl...

Do you like ?0

Read more -

Why not choosing custom flight tags as a gift?

Why not choosing custom flight tags as a gift?Fabric key tag, made by embroidery or woven is one of our new appli...

Do you like ?0

Read more