The production process and technology of nylon lanyard

Ribbon manufacturers share with you the production process and related processes of nylon lanyards. It is understood that nylon lanyards are suitable for key fire protection units such as petroleum and chemical industry, mechanical metal processing, mechanical assembly and complete machine exterior paint packaging and factory hoisting; nylon lanyards do not damage exterior paint; nylon lanyards are also suitable for power plant unit maintenance Lifting generators and steam turbine rotors, etc.; nylon lanyards are light, fast, wear-resistant, and will not produce sparks when they collide. They are ideal wire rope replacement products.

Nylon lanyard production process:

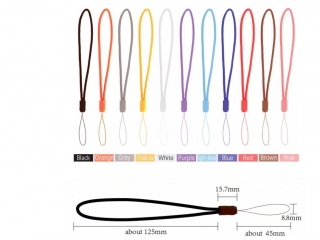

1. Ribbon: Generally, the materials for making thermal transfer slings are nylon, pp, polyester, and high-elastic cotton. The general specifications are 7mm, 9mm, 10mm, 12mm, 15mm, 16mm, 20mm, 25mm, etc. Special widths can also be woven on request.

2. Accessories: Common accessories include metal alloy egg buckles, hook buckles, document clips, etc., and plastic ones include aircraft buckles, mine buckles, insert buckles, safety buckles, etc.

3. Printing: General exhibition lanyards will require the text and patterns that need to be promoted. Printing is divided into ordinary silk screen printing, environmentally friendly glue printing and thermal transfer printing.

4. Assembly: First print, cut to the specified size, add strings, plastic buttons, dispense glue or press metal iron sheets, inspect, and package.

A nylon lanyard is made so that it can be shipped. Classification of nylon lanyards: According to the length, it can be divided into long lanyards and hand ropes. Long lanyards, as the name suggests, are very long and can be hung around the neck. The length of this lanyard is generally between 40--45CM. Nylon lanyards are generally made of document lanyards, exhibition lanyards, mobile phone lanyards, etc.

YYX Weaving reminds you: the production of custom nylon lanyards generally requires first knowing the specifications of nylon lanyards, that is, length and width. Next is the material made of the heat transfer sling, then what accessories are used, and finally whether printing is required. If you need to print the color of the LOGO, etc.... Generally speaking, the wider the ribbon, the more expensive it is to weave. YYX weaving factory is the first choice for the customized wholesale of webbing.

-

Such a beautiful keychain makes people love and hate!

Such a beautiful keychain makes people love and hate!If you are a designer, then lines like "Tune a little bit here", "Help me change t...

Do you like ?0

Read more -

Easy to carry Water Bottle Lanyards buying

Easy to carry Water Bottle Lanyards buying -

Advantages of using personalized printed Silicone Wristbands

Advantages of using personalized printed Silicone Wristbands -

The difference between nylon lanyard vs polyester lanyard - Yiyixing

The difference between nylon lanyard vs polyester lanyard - YiyixingWhat is Polyester Made Lanyards?

When it comes to <...

Do you like ?0

Read more -

Does Wear Cute lanyard can keep in a good mood?

Does Wear Cute lanyard can keep in a good mood?With the growth of age, girls are more and more inclined to adorabl...

Do you like ?0

Read more -

Why not choosing custom flight tags as a gift?

Why not choosing custom flight tags as a gift?Fabric key tag, made by embroidery or woven is one of our new appli...

Do you like ?0

Read more