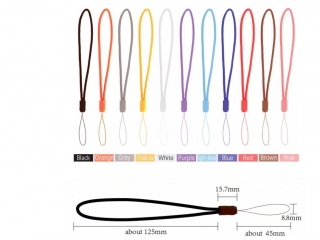

It is used for carrying functions such as exhibitions, labels and certificates. Other names: lanyard, mobile phone rope, lanyard, sling. Generally used in exhibitions, brands and certificates, etc.

Material

There are Tedlon (polyester, poly), nylon, PVC, PU, silicone, resin, metal and other materials.

Polyester:

Polyester (English: POLYESTER, also known as Tedolon), is one of the synthetic fibers, scientific name: polyester fiber, commonly known as polyester (Tedulon). Polyester cross-section is generally round, the side is smooth and bright, its performance as follows :

project performance

Breaking strength dry / wet 5.5---6.3

Tensile Strength 97000 — 114000

Elongation 40%--50%

Specific gravity 1:38

Moisture absorption rate 0.4%

Heat resistance 238C - 240C softening

Melting point 255C — 260C

Acid or alkaline resistance to concentrated hydrochloric acid, the strength is not easy to reduce and decompose in boiling strong alkali.

Solubility and chemical properties Insoluble in general solvents, soluble in hot dimethyl methyl first amine 40 ° C mixed solution of benzoic acid and alkane tetraoxide.

Dyeing: Ice dyeing, soluble vat dyes, etc. <Add auxiliaries>

Anti-corrosion, moth-resistant and not rot, long-term exposure, the strength will decrease.

Hygroscopicity is poor

Finished Product Features Strong and Soft, Good Handfeel, Low Shrinkage, Machine Washable, Drying, Quick Dry, Strong Abrasion Resistance, Easy to Electrostatic Pilling

Production mostly adopts --- step method: conventional polyester chips (raw material ----- spinning ----- stretching ----- heat treatment)

Depending on the spinning process, the products it produces can be divided into the following categories:

(1) Raw silk <RAW/MONO FILAMENT> is the raw material for spinning, and it can also be mixed with other raw materials and woven into products.

(2) POY<PARTIALLY ORIENTED YARN>: Pre-oriented yarn, also known as semi-processed yarn and semi-extended yarn, is a semi-finished product between the final oriented yarn (UDY) and the drawn yarn with the degree of orientation obtained by high-speed spinning. This silk will not be used for knitting because the shrinkage rate is unstable, but it can still be easily stretched. The storage time and environment will easily affect its shrinkage. There are single cake silk and double cake silk.

(3) S.D.Y<SPIN DRAW YARN> fully extended wire.

F.D.Y<FULLY DRAW YARN>

F.O.Y<FULLY ORIENTED YARN>

P.F.Y<POLYESTER FILAMENT YARN>

It is produced by the drafting process. Due to the different production processes, it has different names, but all of them belong to the fully extended yarn, the shrinkage rate is relatively stable, and the knitted fabric is available.

(4) DTY<DRAW TEXTURED YATRN> processing yarn or elastic yarn, and (SETTING YARN> processing shaping yarn.

For products that have been processed and shaped, all or part of the stretching stage is carried out on the same machine as the texturing process. This type of silk is most suitable for knitted fabrics. However, because the brightness of the silk is destroyed by the shaping process, high brightness is required. Best, choose back to FDY products.

The products are white silk, colored silk, inner-splitting silk, medium-stretching silk, low-stretching silk, slub silk, and high-peng silk, etc. Generally, there are:

(A)ITY <INTERMINGLED TEXTURED YARN> Network wire: including low-elasticity network wire, magic color wire, spiral wire and so on.

(B)ECY (Overfeed Wire)

(C) ATY (Air Textured Yarn)

(D)STY (High Twist Yarn)

(E) FTY(FULLY TEXTURED YARN) fully drawn yarn.

In order to develop more and different types of products, spinning mills also add different special processes to various types of silk to turn into more products, such as HIGH TWIST, which can be divided into "S" and "Z". Twist, slub (SLUB), hollow (HOLLOW), thickness (THIN&THICK) and so on.

(F) Special functions.

Recently, with the continuous improvement of technology, various fibers have been developed to have special functions, so various functional fibers came into being, such as UV protection polyester (UV PROTECTION POLYESTER), (THERMOLITE BASE) thermal insulation fibers

CATIONIC DPEABLE Cationic low temperature polyester, conductive <ELECTRICAL CONDUCTIVITY> , antistatic < ANTI-STATIC > , high temperature resistance <HIGH , TEMPERDTURE RESISTANCE , flame retardant < FLAME RETARDANT> , light guide <OPTICAL> , perspiration ( COOLMEX ) and so on.

(G) Special post-processing.

(1) Fibers processed with different forms or components, such as:

Double Shrinkage Yarn: (BI-SHRINKAGE YARN) (B S Y ) is spun from two filaments with different shrink properties during spinning or post-processing.

Bicomponent Yarn: (B1-COMPONTENT YARN) (B C Y) Fibers made from filaments of two components with different shrinkage in cross section.

(2) Pseudo-textured yarn (KNIT DE.KNIT YARN): The embryo yarn is knitted into fabrics and shaped, and then disassembled and made by winding.

(3) Network yarn, pre-oriented yarn or stretch deformation, twisted by high pressure oxygen, the filaments are intertwined to form a periodic network knot.

(4) Others: FALSE-TWIST TEXTURED YARN (FALSE TWIST STABILIZED TEXTURED YARN)

Twist textured yarn ------TWIST TEXTURED YARN

Air Jet Bulk Yarn ------JET BULKED YARN

GEAR CRIMPED YARN ------------GEAR CRIMPED YARN

EDGE CRIMPED YARN -------------EDGE CRIMPED YARN

PP (Polypropylene)

Polypropylene (also known as PP, English name: POLY PROPYLENE) is the trade name of polypropylene fiber, which is a fiber obtained by polymerization and melt spinning from propylene as a raw material. Polypropylene officially started industrial production in 1957 and is a rising star in synthetic fibers. Because polypropylene has the advantages of simple production process, cheap products, high strength and light relative density, polypropylene has developed rapidly. At present, polypropylene is the fourth largest variety of synthetic fibers.

The production of polypropylene includes staple fibers, filaments and split fibers. Polypropylene film fiber is made by first making polypropylene into a film, and then stretching the film to split it into a network of fibrils. Polypropylene is widely used in the manufacture of industrial fabrics, non-woven fabrics, etc. Such as carpets, industrial filter cloths, ropes, fishing nets, building reinforcements, oil-absorbing blankets and decorative cloths. In civilian use, polypropylene can be spun purely or blended with wool, cotton or viscose to make various fabrics. In addition, polypropylene film fibers can be used as packaging materials.

The main physical and chemical properties of polypropylene

1. Shape The longitudinal plane of polypropylene fiber is straight and smooth, and the cross-section is circular.

2. Density The biggest advantage of polypropylene is its light texture. Its density is only 0.91g/cm3, which is the lightest variety of common chemical fibers. Therefore, polypropylene of the same weight can obtain a higher coverage area than other fibers.

3. Strong elongation Polypropylene has high strength, long elongation, high initial modulus and excellent elasticity. So polypropylene has good abrasion resistance. In addition, the wet strength of polypropylene is basically equal to the dry strength, so it is an ideal material for making fishing nets and cables.

4. Hygroscopicity and dyeability Polypropylene has very little hygroscopicity, almost no moisture absorption, and the moisture regain under general atmospheric conditions is close to zero. But it has a wicking effect, passing water vapour through the capillaries in the fabric, but does not have any absorption effect on its own. Polypropylene has poor dyeability and incomplete chromatogram, but it can be compensated by the method of dope dyeing.

5. Acid and alkali resistance Polypropylene has good chemical resistance. Except for concentrated nitric acid and concentrated caustic soda, polypropylene has good resistance to acid and alkali, so it is suitable for use as filter material and packaging material.

6. Lightfastness, etc. Polypropylene has poor lightfastness, poor thermal stability, easy aging, and is not resistant to ironing. But it can improve its anti-aging performance by adding anti-aging agent during spinning. In addition, polypropylene has good electrical insulation, but it is easy to generate static electricity during processing.

hollow cotton

The former DuPont cotton, called Thermolite. That is, the market is collectively referred to as "hollow cotton". It is produced by DuPont and Taiwan Xinli Company. It has been promoted in the market for 40-50 years, and the thermal insulation effect has also been affirmed by the market. But a few years ago, DuPont in the United States has transferred the trademark management rights to INVISTA, so the former DuPont cotton was produced by INVISTA and Xinli Co., Ltd.

Now DuPont has developed a new thermal cotton called "ComforMax", which is divided into three types:

DuPont™ ComforMax™ Classic (DuPont Multilayer Fiber Structure Thermal Insulation): It uses the most advanced textile carding process and contains 4-5 times more fiber layers than other insulation materials. The weight of each single fiber layer is only 5-10 grams per square meter. The secret to this true multi-layer fiber structure guarantees its excellent performance. As a result, it achieves the best thermal insulation at the lightest weight and is an ideal material for the production of high-quality outdoor clothing, sportswear and sleeping bags.

DuPont™ ComforMax™ Premium (DuPont Comfort Control System Insulation): Using DuPont's unique non-woven technology, it still brings you comfort and warmth in harsh climates. High-quality fine denier fibers hold more air than other insulation materials for optimal insulation in the thinnest thickness. The thin layer of non-woven fabric can reflect the heat radiated by the human body and reduce the heat from escaping to the outside. The unique non-woven fabric structure is not only windproof and waterproof, but also extremely breathable. Its open pore structure can effectively prevent the uncomfortable feeling caused by the accumulation of sweat.

ComforMax™ Premium (DuPont Comfort Control System Insulation Liner) is lightweight and warm, durable, soft texture, excellent wind resistance, excellent breathability, water resistance up to 1200 mm water column, and effective resistance to fiber slippage and leakage.

ComforMax provides better insulation, longer life, thinner and softer than previous Thinsulate from DuPont's Thermolit and 3M. ComforMax™ is currently in the early stage of market promotion. I believe that in the near future, you will soon be able to see related products in the market, and you will be able to better understand what is the best - light - thin - warm ——

PVC (polyvinyl chloride)

Polyvinyl chloride (PVC, full name: POLYVINYL CHLORIDE) is synthesized from ethylene and hydrogen chloride (calcium carbide route) or ethane, ethylene and chlorine (petrochemical route) into vinyl chloride monomer, and then polymerized into polyvinyl chloride resin. According to the polymerization process, it can be divided into bulk, suspension, emulsion, solution and other polymerization products, of which more than 80% are suspension polymerization products, and emulsion polymerization resin accounts for about 10%, mainly used for paste materials. Bulk Polymerization Yibin Tianyuan Chemical Plant has introduced French technology and is currently only in the early stage of preparation. The amount of solution polymerized resin is not much, and there is no such product in China.

At present, my country's suspension polymer resin is divided into seven types of products according to molecular weight, and each type is divided into two types: compact type and loose type according to its particle shape. The particle size of the resin particles is about 100~150 microns. They are formed by agglomeration of countless particles of 0.1 microns in size. The entire surface of some particles is covered with a "film". The film is relatively firm and difficult to destroy. This is a compact resin. , its plasticizer penetration ability is poor. The "film" of the loose resin is very thin and not completely covered, which is conducive to the penetration of the plasticizer into the particles. Its molecules are arranged in a random structure, and the crystallinity is at most 5% to 10% (including a small amount of crystallinity of 20%. structure). The weight average molecular weight is about 50,000 to 150,000, and the size of the molecular weight is closely related to melt viscosity, processing temperature, product properties, and use. PVC is white powder or microbeads, transparent after plasticization and easy to color. Unplasticized products are tough, and the degree of hardness and mechanical properties can be freely adjusted by adding plasticizers. Flame retardant, self-extinguishing, good electrical insulation. Water resistance, good chemical stability, acid and alkali resistance, but soluble in most solvents. The thermal stability of the resin is poor, but it can be overcome by adding a thermal stabilizer.

PVC can be moulded, laminated, injection moulded, extruded, calendered, blow-moulded, injection-blow, foamed, sprayed, rotationally formed, vacuum thermoformed, machined, welded, bonded, printed, surface decorated. Application: Calendering, extrusion, blow molding, film, pipe, sheet, profile, monofilament, rope, fishing float, wire and cable material, container, bottle, transparent pellet, synthetic wood, building material, agricultural film, Blood transfusion bags, plastic doors, windows, interior decoration materials, laminates, chemical equipment, etc.

PVC paste resin is produced by emulsion seed polymerization, micro-suspension polymerization and micro-suspension seed polymerization. Emulsion polymerization: It has high molecular weight and tiny particles (usually 0.2~2 microns, preferably 0.5~1 microns), and there is no film on the surface of the particles, so it can absorb a large amount of plasticizer. When making paste, the amount of plasticizer is small and the viscosity is low; the paste resin has good stability during the molding process (the change of paste viscosity is small). The resin particle shape is spherical, the particle size distribution is wide, the lubricity is good, the paste viscosity is low, the fluidity is good, the amount of plasticizer is small, and the paste stability is good. The paste resin has more impurities and poor electrical properties, high water absorption, thermal stability, transparency and color are not as good as the suspension resin. Other properties are the same as suspension polymer resins.

The molding process of emulsion resin can be slush molding, rotary molding, lamination, coating, dipping, foaming, bonding, printing, surface decoration, application: slush molding toys, rotary molding such as balls, etc. The coating method is used to manufacture artificial leather, wallpaper, tarpaulins, ponchos, conveyor belts, and the dipping method to manufacture gloves and other impregnated products.

The full name is Polyvinylchlorid, the main ingredient is polyvinyl chloride, and other ingredients are added to enhance its heat resistance, toughness, ductility, etc. It is a well-loved, popular and widely used synthetic material in the world today. Its global usage is the second highest among all synthetic materials. According to statistics, in 1995 alone, the production of PVC in Europe was about 5 million tons, while its consumption was 5.3 million tons. In Germany, PVC production and consumption average 1.4 million tons. PVC is being produced and applied worldwide at a growth rate of 4%. In recent years, the growth of PVC in Southeast Asia has been particularly significant, thanks to the urgent need for infrastructure construction in Southeast Asian countries. Among the materials that can produce three-dimensional surface films, PVC is the most suitable material.

PVC can be divided into soft PVC and hard PVC. Among them, hard PVC accounts for about 2/3 of the market, and soft PVC accounts for 1/3. Soft PVC is generally used for the surface of floors, ceilings and leather, but because soft PVC contains softeners (this is also the difference between soft PVC and hard PVC), it is easy to become brittle and difficult to store, so its scope of use is limited. Hard PVC does not contain softeners, so it has good flexibility, easy to form, not easy to be brittle, non-toxic and pollution-free, and has a long storage time, so it has great development and application value. Hereinafter referred to as PVC. The essence of PVC is a vacuum blister film, which is used for surface packaging of various panels, so it is also called decorative film and adhesive film, and is used in many industries such as building materials, packaging, and medicine. Among them, the building materials industry accounts for the largest proportion, accounting for 60%, followed by the packaging industry, and several other small-scale application industries.

PVC is a polyvinyl chloride plastic with bright color, corrosion resistance, firmness and durability. Due to the addition of some toxic auxiliary materials such as plasticizers and anti-aging agents in the manufacturing process, its products generally do not store food and medicine.

PVC is actually a polymer substance of vinyl.

Simply put, an aqueous solution of salt is chemically decomposed under the action of an electric current. This process produces chlorine, caustic soda and hydrogen. Refining, cracking petroleum or gasoline produces ethylene. When chlorine and ethylene are mixed, dichloroethylene is produced; dichloroethylene can be converted to produce chlorinated vinyl, which is the basic building block of polyvinyl chloride. The polymerization process links chlorinated vinyl molecules together to form PVC chains. The PVC produced in this way is in the form of a white powder. It cannot be used alone, but can be mixed with other ingredients to create many products.

Chlorinated vinyl was first synthesized in the laboratory of Justus von Liebig in 1835. Polyvinyl chloride was synthesized by Baumann in 1872. But the first commercial products of PVC were not produced in the United States until the 1820s, and large-scale production in Europe did not begin within the next 20 years.

Polyvinyl chloride has outstanding characteristics such as abundant raw materials (petroleum, limestone, coke, salt and natural gas), mature manufacturing process, low price, and wide range of uses. It has become the second largest general-purpose resin in the world after polyethylene resin, accounting for 29% of the world's total consumption of synthetic resins. PVC is easy to process and can be processed by molding, lamination, injection molding, extrusion molding, calendering, blow molding, etc. Polyvinyl chloride is mainly used to produce soft plastic products such as artificial leather, film, wire sheath, etc., and can also produce hard plastic products such as plates, doors and windows, pipes and valves.

Polyvinyl chloride has flame retardant (flame retardant value above 40), high chemical resistance (resistance to concentrated hydrochloric acid, 90% sulfuric acid, 60% nitric acid and 20% sodium hydroxide), mechanical strength And the advantage of good electrical insulation. However, its heat resistance is poor, the softening point is 80 °C, and it begins to decompose and discolor at 130 °C, and precipitate HCI.

nylon:

The origin of the word nylon is unclear. Many people say it is a combination of the abbreviations of NY (New York in the United States, New York in English) and Lon (London in the United Kingdom, English London), the two places where nylon was first produced. But this claim is baseless. In 1940, someone at DuPont said that Nyl was found at random, and on was because the English word for many fibers (such as cotton, English Cotton) ended with on. In an article published by DuPont in 1978, it was said that they originally intended to call it No-Run, but later changed it to Nylon, nylon, in order to make it sound better.

Another common myth is that nylon is an acronym for Now You, Lazy Old Nippon. The background is the flood of cheap Japanese textiles hitting Western society in the 1930s. Nylon is therefore seen as a competitive product against Japanese textiles. Although the word nylon is very popular, it has never been used as a trademark or protected by a trademark.

During World War II, the Allies used nylon parachutes (previously generally made of Asian silk), and other military supplies such as tires, tents, and ropes were also made of nylon. It was even used to make paper for printing American currency. At the beginning of the war, cotton accounted for 80% of the fiber raw material, and the other 20% was only wood fiber. By August 1945, the percentage of cotton had dropped to 75%, while the percentage of man-made fibers had risen to 25%.

Polyamide, commonly known as Nylon, English name Polyamide (PA), is a general term for thermoplastic resins containing repeating amide groups - [NHCO] - on the main chain of the molecule. Including aliphatic PA, aliphatic-aromatic PA and aromatic PA. Among them, aliphatic PA has many varieties, large output and wide application, and its name is determined by the specific number of carbon atoms of the synthetic monomer.

The main varieties of nylon are nylon 6 and nylon 66, which are absolutely dominant, followed by nylon 11, nylon 12, nylon 610, nylon 612, and nylon 1010, nylon 46, nylon 7, nylon 9, nylon 13, new There are nylon 6I, nylon 9T and special nylon MXD6 (barrier resin), etc. There are many kinds of nylon modified, such as reinforced nylon, monomer casting nylon (MC nylon), reaction injection molding (RIM) nylon, aromatic nylon , transparent nylon, high impact (super tough) nylon, electroplated nylon, conductive nylon, flame retardant nylon, nylon and other polymer blends and alloys, etc., to meet different special requirements, widely used as metal, wood and other traditional materials replacement Supplies, as various structural materials.

Nylon is the most important engineering plastic, and its output ranks first among the five general engineering plastics

Performance: Nylon is a tough angular translucent or milky white crystalline resin. As an engineering plastic, the molecular weight of nylon is generally 15,000 to 30,000. Nylon has high mechanical strength, high softening point, heat resistance, low friction coefficient, and wear resistance. Self-lubricating, shock-absorbing and sound-absorbing, oil resistance, weak acid resistance, alkali resistance and general solvent resistance, good electrical insulation, self-extinguishing, non-toxic, odorless, good weather resistance, poor dyeing. The disadvantage is that the water absorption is large, which affects the dimensional stability and electrical properties. Fiber reinforcement can reduce the water absorption of the resin, so that it can work under high temperature and high humidity. Nylon has a very good affinity with glass fiber.

Among nylons, nylon 66 has the highest hardness and rigidity, but the worst toughness. Various nylons are sorted by toughness: PA66<PA66/6<PA6<PA610<PA11<PA12.

The flammability of nylon is UL94v-2 grade, the oxygen index is 24-28, the decomposition temperature of nylon is >299℃, and spontaneous combustion occurs at 449~499℃.

Nylon has good melt fluidity, so the wall thickness of the product can be as small as 1mm.

Comparison of various materials:

1. Viscose (moisture absorption and easy to dye):

It is a man-made cellulose fiber, which is obtained by solution spinning. Due to the inconsistent coagulation rate of the fiber core layer and the outer layer, a skin-core structure is formed (obviously seen from the cross-sectional slice). Viscose is the most hygroscopic among ordinary chemical fibers, with good dyeing properties, good wearing comfort, poor elasticity of viscose, poor strength in wet state, and poor abrasion resistance, so viscose is not washable and has poor dimensional stability. The specific gravity is large, the fabric is heavy, and it is resistant to alkali and not acid.

Viscose fiber is widely used, and it is used in almost all types of textiles, such as filament for lining, beautiful silk, flags, streamers, tire cord, etc.; short fiber for cotton-like, wool-like, blended, interwoven, etc.

2. Polyester (stiff and not wrinkled):

Features: high strength, good impact resistance, heat resistance, corrosion resistance, moth resistance, acid and alkali resistance, good light resistance (second only to acrylic fiber), 1000 hours of exposure, 60-70% strength, poor hygroscopicity , It is difficult to dye, the fabric is easy to wash and dry, and the shape retention is good. Features "Wash and Wear"

use:

Filament: often used as low-elasticity filament to make various textiles;

Staple fiber: cotton, wool, hemp, etc. can be blended, industrial: tire cord, fishing net, rope, filter cloth, insulation materials, etc. It is currently the largest amount of chemical fiber.

3. Nylon (strong and wear-resistant):

The biggest advantage is that it is strong and wear-resistant, which is the best one. Low density, light fabric, good elasticity, fatigue resistance, good chemical stability, alkali resistance but not acid resistance!

The biggest disadvantage is that the sun resistance is not good, the fabric will turn yellow after a long time, the strength will decrease, and the moisture absorption is not good, but it is better than acrylic and polyester.

Uses: Filament, mostly used in knitting and silk industries; staple fiber, mostly blended with wool or wool-type chemical fiber, for gabardine, vanedin, etc. Industry: cords and fishing nets, can also be used as carpets, ropes, conveyor belts, screens, etc.

4. Acrylic fiber (bulky and lightfast):

The performance of acrylic fiber is very similar to wool, so it is called "synthetic wool".

Molecular structure: Acrylic fiber is very unique in its internal large substructure, showing an irregular helical conformation, and there is no strict crystalline region, but there are high-order and low-order arrangements. Because of this structure, acrylic has good thermal elasticity (bulked yarn can be processed), the density of acrylic is smaller than wool, and the fabric has good thermal insulation.

Features: good sunlight resistance and weather resistance (rank first), poor moisture absorption, difficult to dye.

Pure acrylonitrile fiber, due to its tight internal structure, has poor wearing performance, so by adding the second and third monomers, its performance is improved, the second monomer improves: elasticity and feel, and the third monomer improves dyeability.

Uses: Mainly for civilian use, it can be spun or blended to make a variety of wool, wool, blankets, sportswear: artificial fur, plush, bulked yarn, water hose, parasol cloth, etc.

Five, vinylon (water-soluble moisture absorption):

The biggest feature is that it has high hygroscopicity and is the best among synthetic fibers, known as "synthetic cotton". The strength is worse than that of brocade and polyester, the chemical stability is good, and it is not resistant to strong acid and alkali. Sunlight resistance and weather resistance are also very good, but it has the worst resistance to dry heat but not wet heat (shrinkage), the fabric is easy to wrinkle, the dyeing is poor, and the color is not bright.

Uses: Multi and cotton blends: muslin, poplin, corduroy, underwear, canvas, tarpaulin, packaging materials, work clothes, etc.

6. Polypropylene (lightweight and warm):

Polypropylene fiber is the lightest fiber among common chemical fibers. It is hardly hygroscopic, but has good wicking ability, high strength, dimensionally stable fabrics, good abrasion resistance and good chemical stability. But: poor thermal stability, not resistant to sunlight, easy to aging and brittle damage.

Uses: It can knit socks, mosquito nets, quilts, warm fillers, wet diapers, etc. Industry: carpets, fishing nets, canvas, water hoses, medical tapes instead of cotton gauze, as sanitary products.

Seven, spandex (elastic fiber):

The elasticity is the best, the strength is the worst, the moisture absorption is poor, and it has good light resistance, acid resistance, alkali resistance and wear resistance.

Uses: Spandex is widely used in underwear, women's underwear, casual wear, sportswear, socks, pantyhose, bandages and other textile fields, medical fields, etc. Spandex is a highly elastic fiber necessary for high-performance clothing that pursues movement and convenience. Spandex stretches 5-7 times longer than it is, so it's comfortable to wear, soft to the touch, and wrinkle-free, keeping its original silhouette at all times.

use diagram

The main products include identification card rope series (such as: slings, suspenders, lanyards, lanyards suitable for brands, work cards, badges, badges, exhibition cards), digital product rope series (such as: suitable for mobile phones , MP3, MP4, U disk, camera slings, slings, lanyards, lanyards, zipper belts, mobile phone wipes), travel goods rope series (mainly luggage belts, carabiner belts, beverage slings, kettle slings) , Fashion jewelry rope series (mainly hand straps, wrist straps, finger straps, carry straps, belts, belts, glasses straps, shoelaces), pet strap series, special strap series (such as: two-end buckle straps, anti-type sling).

Production process

It can be roughly divided into three major links: webbing, printing, and assembly. There are other details involved in each link, please see the specific content below.

1. Ribbon

1 Prepare the yarn

For silk screen printing, if the color of the lanyard requested by the customer is a common color, such as red, black, etc., you can directly buy the yarn and then weave it; if it is an uncommon color, the factory will buy white yarn and dye it yourself Then weave the belt.

2 barrels

The yarn purchased from the factory or the yarn after dyeing needs to be wound into a barrel thread suitable for the loom. The factory machine uses iron loops, and the purchased thread is not suitable for direct wrapping on the machine.

3 webbing

The worker puts the wound thread on the weaving machine for weaving. When weaving, the white thread is usually more dirty, so a special machine is needed to produce it. After weaving, it is placed in a fixed place. , can be used.

Some ribbons are woven flat, while others are round.

2. Printing (the lanyard printing part is divided into two types: silk screen printing and thermal transfer printing)

(1) Screen printing process:

1 ironing

The newly woven lanyard is not flat and needs to be ironed with an ironing machine before printing.

2 printing

When the factory is actually printing, there are two methods that are commonly used at present: screen printing and thermal transfer printing.

3 Screen printing

① Fix the lanyard on the printing table. There is a layer of primer on the table to fix the lanyard and prevent the lanyard from moving during the printing process. This glue generally does not stick to the surface of the lanyard.

② The production of silk screen version. After the technician gets the original logo, he first traces the drawing, and then makes the film called the film.

"Film" is the transliteration of "Film". Film is a transparent film with a film on one side called a matte surface, and a film without a film on the other side to reflect light. The matte surface is not very reflective. If you have seen the bottom of the traditional photo, you will know that the principle is the same, but the composition of the film base and the medicine film are different. The film is divided into four colors (CMYK) and spot color film. There are four things like slides that are stacked together to form a complete color image, which needs to be taken to the printing house to make the plate and divided into four overprints.

The screen printing plate is a screen printing plate made by using photosensitive material by photo-engraving method (the screen holes of the graphic part on the screen printing plate are through holes, and the screen holes of the non-graphic part are blocked). During printing, through the extrusion of the squeegee, the ink is transferred to the substrate through the mesh of the graphic part to form the same graphic as the original. Screen printing equipment is simple, easy to operate, easy to print and plate making, low cost, and strong adaptability. Screen printing is widely used in common prints: color oil paintings, posters, business cards, binding covers, commodity signs, and printed and dyed textiles.

③ Because it is printed by means of through-hole ink leakage, several screen versions of the Logo have to be opened for several colors. Several screen versions of different colors form a complete logo.

④ Fix the screen printing plate in the wooden frame and start printing. Use the corresponding color ink for each plate, and use the squeegee to squeeze to color the through hole part. There are obvious signs on the printing table, the operator can know the movement The interval of the frame, the interval of each move is the same.

⑤ After printing this side, stick it on the desktop and start printing the other side

⑥ Screen printing may appear incomplete printing, you can see if you want to repeat the screen printing according to the situation.

⑦ After screen printing, the logo should be dried.

(2) The thermal transfer process of the lanyard:

① Process introduction. Thermal transfer printing is a new printing process that has been introduced from abroad for more than 10 years. The process printing method is divided into two parts: transfer film printing and transfer processing. The transfer film printing adopts dot printing (resolution up to 300dpi), and the pattern is pre-printed on the surface of the film. The printed pattern is rich in layers, bright in color and ever-changing. , small chromatic aberration, good reproducibility, can meet the requirements of the designer, and is suitable for mass production; transfer processing through the thermal transfer machine one-time processing (heating and pressure) to transfer the exquisite pattern on the transfer film to the product. The surface, after molding, the ink layer and the surface of the product are integrated, which is realistic and beautiful, which greatly improves the grade of the product. However, due to the high technical content of this process, many materials need to be imported.

② There are two types of films generally used. One is roll type and the other is sheet type. These papers are made by professional factories that make this kind of paper. The roll type is calculated according to the meter, while the The leaflet type is calculated according to the sheet, and it is cheaper to calculate the leaflet type.

Rolled: A continuous piece of paper, similar to the total length of the lanyard printed at one time. The lanyard and roll are rolled, contacted, and then heated in a heat transfer machine to print the logo on the roll to In the lanyard. The used drum is wrapped around another drum.

Sheet-fed: For sheets of paper, the factory needs to align the lanyard with the sheets of paper, and then heat them together in a heat transfer machine to print the pattern on the paper directly on the lanyard. The alignment method of the lanyard and the paper is to open a piece of paper, and then put the lanyard on the paper. The edge of the lanyard and the edge of the pattern are exactly opposite in size, and there should be no deviation, and then put them into the heat transfer machine together. inside.

Three, assembly.

1 Cutting of lanyards. Since lanyards are screen-printed in batches, they should be cut into lanyards one by one after printing. There are generally two ways of positioning: one is to draw a corresponding line on the table, and the position is matched; The other is: mark is left in the screen printing. In this way, the operator uses the steel wire to energize, presses down with the steel wire according to the mark, and uses the high temperature to melt the lanyard to cut open. Use the high temperature steel wire to cut to avoid the occurrence of wire drawing .

2 Assembly of accessories.

For sewing. You can trim the thread after sewing.

-

Such a beautiful keychain makes people love and hate!

Such a beautiful keychain makes people love and hate!If you are a designer, then lines like "Tune a little bit here", "Help me change t...

Do you like ?0

Read more -

Easy to carry Water Bottle Lanyards buying

Easy to carry Water Bottle Lanyards buying -

Advantages of using personalized printed Silicone Wristbands

Advantages of using personalized printed Silicone Wristbands -

The difference between nylon lanyard vs polyester lanyard - Yiyixing

The difference between nylon lanyard vs polyester lanyard - YiyixingWhat is Polyester Made Lanyards?

When it comes to <...

Do you like ?0

Read more -

Does Wear Cute lanyard can keep in a good mood?

Does Wear Cute lanyard can keep in a good mood?With the growth of age, girls are more and more inclined to adorabl...

Do you like ?0

Read more -

Why not choosing custom flight tags as a gift?

Why not choosing custom flight tags as a gift?Fabric key tag, made by embroidery or woven is one of our new appli...

Do you like ?0

Read more